ABOUT US:

OUR HONORS:

WELDING PRODUCTS DISCRIPTIONS:

PACKAGE:

NW: 250kg/Pail

4Pails/pallet, 22pallets/1x20'GP

Total N.W.: 22tons/1x20'GP

Total G.W.: 23.8tons/1x20'GP

TOP TIPS:

Basic Terms and Conditions:

Our Featured Welding Products List:

Welding Materials

Welding Consumable

Gas Shielding Solid Welding Wire:

1. AWS ER70S-6 CO2 Gas Shielded Welding Wire

2. MIG Welding Wire ( MIG wire )

3. TIG Welding Wire ( TIG wire )

4. MAG Welding Wire (MAG wire )

5. Drum Welding Wire ( ER70S-6 welding wire )

6. AWS ER70S-6 Welding Wire( CO2 Shielding Gas Wire )

7. AWS ER70S-G Welding Wire( CO2 Shielding Gas Wire )

Submerged Arc Welding Wire (Solid Solder Wire):

10. H08A/EL12 Submerged Arc Welding Wire

11. H10Mn2/ EH14 Submerged Arc Welding Wire ( SAW wire )

12. H08MnA/ EM12(K) Submerged Arc Welding Wire ( SAW wire )

13. Welding Rod (Welding Electrode E6013)

14. Round Bar

15. PS Strand( 1x7 wires with ASTM A416 TS: 1860MPa )

16. Steel Wire Rod for Welding wire(ER50-6, H08A, H08MnA, H10Mn2, Q195/235)

17. High Quality Steel Wire Cord

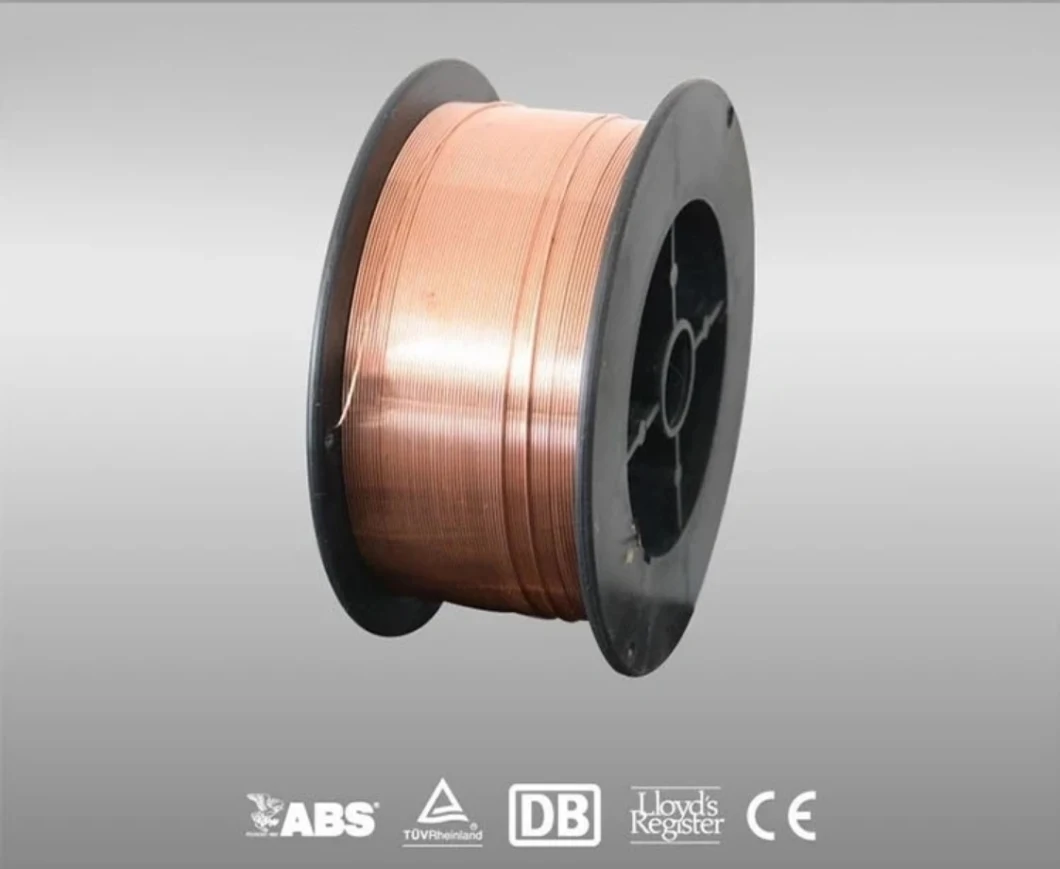

MIG Welding Wire Descriptions:

MIG Welding Wire is a kind of mild steel copper coated welding wire, suitable for 100% CO2 and Argon& CO2 mixed gas protective welding with stable feasibility, excellent welding seams, less spatters and excellent welding process properties.

Main Applications:

This series of welding wire is used for welding low carbon steel and low alloy steel structure,

√ ships,

√ vehicles,

√ bridges,

√ boilers and buildings,

√ carbon steel and 500MPa low alloy steel and etc.

Special Introduction MIG Wire Specs :

Why to Choose Our Welding Products:

1. Low welding costs.

2. High productivity and low electricity consumption.

3. Easy to operate. All-position welding.

4. Very low hydrogen content in the weld and lower nitrogen content. Excellent crack-resistance.

5. Little deformation after welding.

6. Suitable for welding thin, medium and thick plates.

7. high depositing speed,

8. excellent depositing efficiency,

9. stable arc,

10. little splash,

11. good welding seam.

12. Suitable for all-position welding.

Important Notes about How to Store:

1). The wires must be stocked in dry circumstances. Don't open the anti-moisture package of spools to avoid rusting.

2). Before welding, rust, oil, water and impurities are to be moved from the surfaces of mother body welded.

Our Outstanding Advantages:

1. 24 hours on-line services, such as Email, Whatsapp, WeChat, Skype.

2. Professional technique support

3. OEM and ODM available

4. Delivery time: within 15~20days after confirming purchase order

5. Trial order and sample order are available

6. Accept the third party inspection before shipment

7. Strict quality self-control system to guarantee the shipment

OEM Services:

Warehouse View:

Thank you for your time and considerations

| Manufacturer | Weifang Forward Welding Materials Co., Ltd. | ||

| Activities | Sales MIG Welding Wire and Submerged Arc Welding Wire | ||

OUR HONORS:

| Honors | the member of China Iron & Steel Association | ||

| China Chamber of Commerce of Metals Minerals & Chemicals Imp. & Exp. | |||

| top 500 enterprises in manufacture industry of China | |||

| top 100 enterprises in Shandong Province | |||

| top 10 enterprises in Weifang City | |||

WELDING PRODUCTS DISCRIPTIONS:

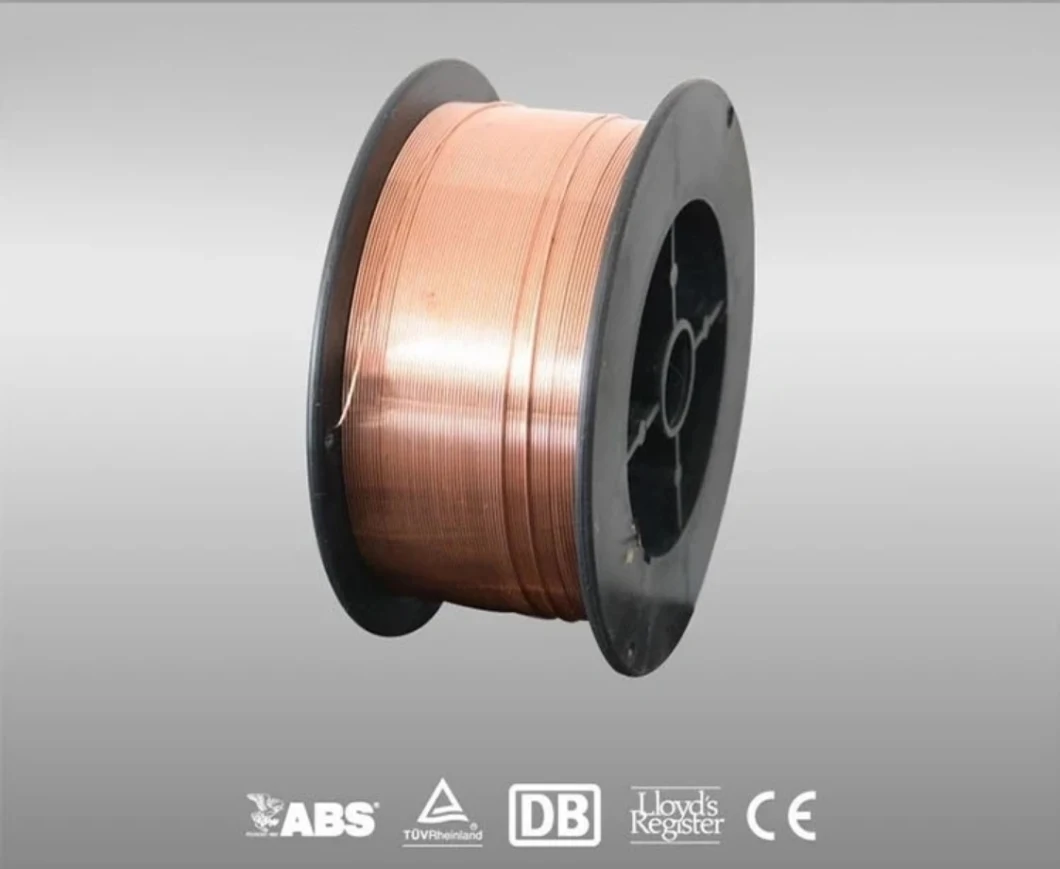

| Product Name: | MIG welding wire | ||

| Grade: | AWS A5.18 ER70S-6 | ||

| GB/T ER50-6 | |||

| Certificate: | CCS, ABS, DNV, NK, LR, BV, GL, KR, CWB, BKI and etc. | ||

PACKAGE:

| Available Size | Package1 | Package2 | Package3 |

| 0.8mm | 5kg/D200 Plastic Spool | 15kg/D270 Plastic Spool | / |

| 0.9mm | 5kg/D200 Plastic Spool | 15kg/D270 Plastic Spool | / |

| 1.0mm | 5kg/D200 Plastic Spool | 15kg/D270 Plastic Spool | 250kg/pail |

| 1.2mm | / | 15kg/D270 Plastic Spool | 250kg/pail |

| 1.6mm | / | 15kg/D270 Plastic Spool | 250kg/pail |

4Pails/pallet, 22pallets/1x20'GP

Total N.W.: 22tons/1x20'GP

Total G.W.: 23.8tons/1x20'GP

TOP TIPS:

Basic Terms and Conditions:

| Price Terms | CIF, CFR | ||

| Terms of Payment | 30% TT in advance, 70% balance against BL copy | ||

| Irrevocable L/C at sight | |||

| Delivery Time | within 5~30days after receipt of deposit | ||

| Place of Origin | Weifang, Shandong, China | ||

| Port of Loading | Qingdao Port | ||

| MOQ | 20tons | ||

Our Featured Welding Products List:

Welding Materials

Welding Consumable

Gas Shielding Solid Welding Wire:

1. AWS ER70S-6 CO2 Gas Shielded Welding Wire

2. MIG Welding Wire ( MIG wire )

3. TIG Welding Wire ( TIG wire )

4. MAG Welding Wire (MAG wire )

5. Drum Welding Wire ( ER70S-6 welding wire )

6. AWS ER70S-6 Welding Wire( CO2 Shielding Gas Wire )

7. AWS ER70S-G Welding Wire( CO2 Shielding Gas Wire )

Submerged Arc Welding Wire (Solid Solder Wire):

10. H08A/EL12 Submerged Arc Welding Wire

11. H10Mn2/ EH14 Submerged Arc Welding Wire ( SAW wire )

12. H08MnA/ EM12(K) Submerged Arc Welding Wire ( SAW wire )

13. Welding Rod (Welding Electrode E6013)

14. Round Bar

15. PS Strand( 1x7 wires with ASTM A416 TS: 1860MPa )

16. Steel Wire Rod for Welding wire(ER50-6, H08A, H08MnA, H10Mn2, Q195/235)

17. High Quality Steel Wire Cord

MIG Welding Wire Descriptions:

MIG Welding Wire is a kind of mild steel copper coated welding wire, suitable for 100% CO2 and Argon& CO2 mixed gas protective welding with stable feasibility, excellent welding seams, less spatters and excellent welding process properties.

Main Applications:

This series of welding wire is used for welding low carbon steel and low alloy steel structure,

√ ships,

√ vehicles,

√ bridges,

√ boilers and buildings,

√ carbon steel and 500MPa low alloy steel and etc.

Special Introduction MIG Wire Specs :

| Standards and steel grade | GB | ER50-6 | ER50-G |

| AWS | ER70S-6 | ER70S-G | |

| Specificationφ(mm) | 0.8-1.6 | 0.8-1.6 | |

| Welding wire chemical composition | C | 0.06-0.15 | ≤0.10 |

| Mn | 1.40-1.85 | 1.40-1.90 | |

| Si | 0.80-1.15 | 0.55-1.10 | |

| P | ≤0.025 | ≤0.030 | |

| S | ≤0.035 | ≤0.030 | |

| Cr | - | Al≤0.10 | |

| Ni | - | Ti0.12-0.20 | |

| Cu | ≤0.50 | ≤0.50 | |

| Mechanical Properties of deposited metal | σs(MPa) | ≥420 | ≥420 |

| σb(Mpa) | ≥500 | 500-660 | |

| σ5(%) | ≥22 | ≥22 | |

| AKV J(ºC) | ≥27(-29) | ≥47(-20) | |

| Shielded Gas | CO2 | CO2 | |

| Main Applications | For welding low carbon and high strength steel structures of 500MPa | For welding low carbon and high strength steel structures of 500MPa, also used for high current welding | |

Why to Choose Our Welding Products:

1. Low welding costs.

2. High productivity and low electricity consumption.

3. Easy to operate. All-position welding.

4. Very low hydrogen content in the weld and lower nitrogen content. Excellent crack-resistance.

5. Little deformation after welding.

6. Suitable for welding thin, medium and thick plates.

7. high depositing speed,

8. excellent depositing efficiency,

9. stable arc,

10. little splash,

11. good welding seam.

12. Suitable for all-position welding.

Important Notes about How to Store:

1). The wires must be stocked in dry circumstances. Don't open the anti-moisture package of spools to avoid rusting.

2). Before welding, rust, oil, water and impurities are to be moved from the surfaces of mother body welded.

Our Outstanding Advantages:

1. 24 hours on-line services, such as Email, Whatsapp, WeChat, Skype.

2. Professional technique support

3. OEM and ODM available

4. Delivery time: within 15~20days after confirming purchase order

5. Trial order and sample order are available

6. Accept the third party inspection before shipment

7. Strict quality self-control system to guarantee the shipment

OEM Services:

Warehouse View:

Thank you for your time and considerations